OEM/ODM Factory Cold Room Machine - Meat pork beef cold room Supplier – New Star

OEM/ODM Factory Cold Room Machine - Meat pork beef cold room Supplier – New Star Detail:

Meat pork beef cold room

Understanding the correct meat cold room procedures whether frozen or chilled, is important if you want produce that is as fresh, delicious and safe as possible.

Harmful bacteria begin to develop in raw meat from the moment an animal is slaughtered, making storage an incredibly time sensitive process. If you want or need to prolong the life of your meat for as long as possible, it’s crucial that you follow the correct safe storage procedures.

Usually the temperature dropped below -18 ℃, the food freezing rate was high, the microorganisms and enzymes basically stopped moving and growing, and the oxidation was also very slow. Therefore, the food can be stored for a longer period of time and has better frozen quality. In addition, frozen food also requires that the temperature in the storehouse be relatively stable. Excessive temperature fluctuations will cause spoilage of the food.

Meat cold room is mainly used for the cold processing of meat carcasses such as pigs, cattle, and sheep.

1, Pre-cooling room

The freezing point of meat juice is -0.6 ~ -1.2 ℃. When the carcass temperature after slaughtering is about 35 ℃, it is sent to a cold room. The designed room temperature is about 0 ~ -2 ℃. The meat temperature is reduced to 4 ℃ in the cold room. Due to the small heat capacity and thermal conductivity of the air, increasing the air flow rate can increase the cooling rate. However, an excessively strong air flow rate cannot increase the cooling rate compared with the same period of the previous year, but it will greatly increase the dry shrinkage loss and power consumption of the meat surface. Therefore, in the cooling process, the wind speed in the cargo room of the cold room is suitable not to exceed 2m / s, and generally the above 0.5m / s is used. The air circulation times are 50 ~ 60 times / h, and the cooling time is 10 ~ 20h. The average dry body consumption is about 1.3%.

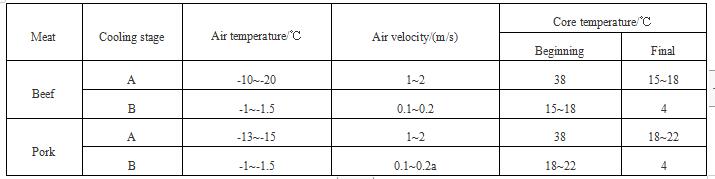

2, Cooling processing

A, The temperature is -10 ~ -15 ℃, the air velocity is 1.5 ~ 3m / s, and the cooling time is 1-4h. The average enthalpy value of the meat at this stage is about 40kj / kg, which makes the surface of the meat form a layer of ice. Not only reduces the dry consumption, but also accelerates the cooling process (the thermal conductivity of ice is 4 times that of water).

B, The cold room temperature is about -1 ℃, the air velocity is 0.5 ~ 1.5m / s, and the cooling time is 10 ~ 15h, so that the surface temperature gradually increases and the internal temperature gradually decreases, so that the temperature of the body is balanced until the thermal center temperature reaches 4 ℃. The meat cooled by this method has good color, aroma, taste and tenderness, which shortens the cooling time and reduces the dry consumption by 40% to 50%. The following picture shows the process conditions for rapid cooling of meat.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for OEM/ODM Factory Cold Room Machine - Meat pork beef cold room Supplier – New Star , The product will supply to all over the world, such as: Japan, Malaysia, Jamaica, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.